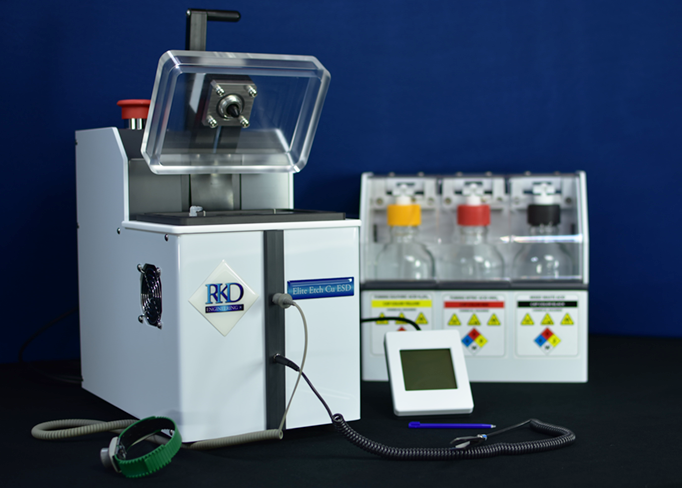

Elite Etch Cu ESD 7200

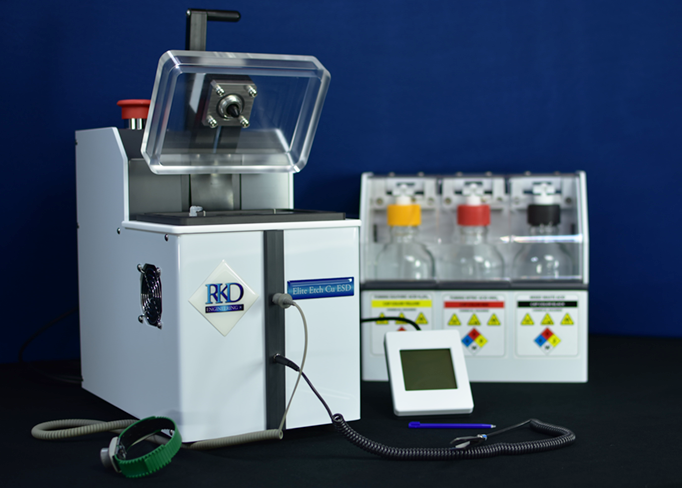

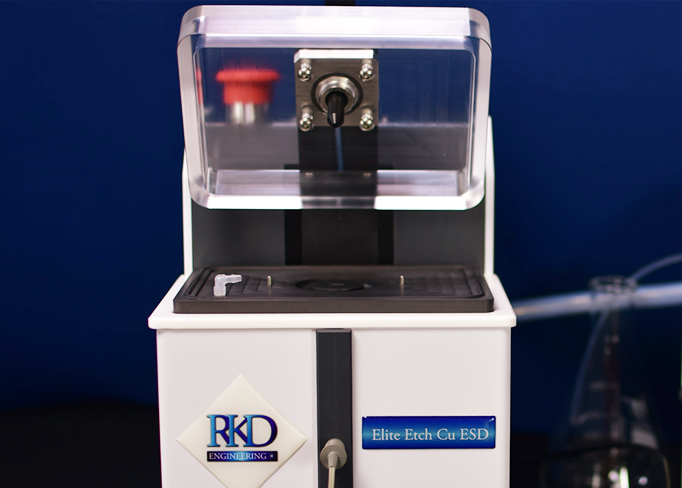

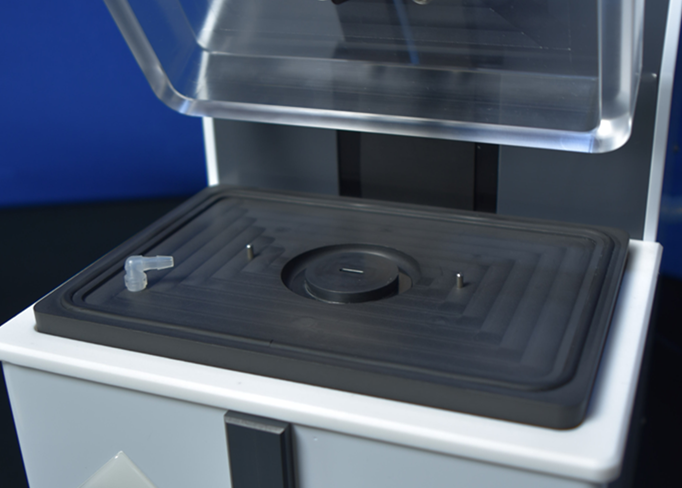

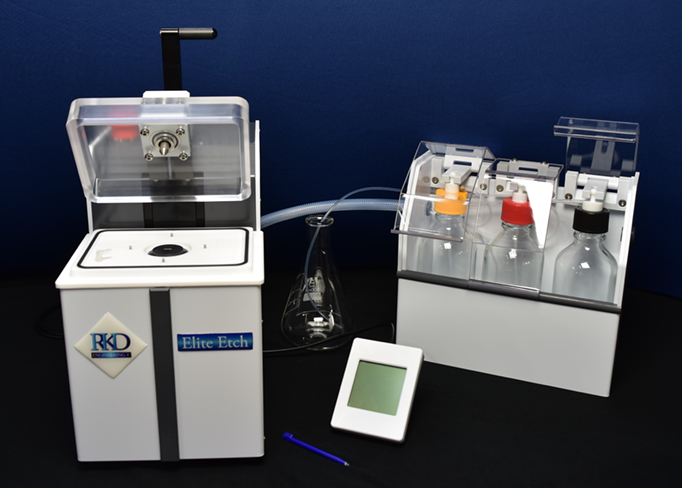

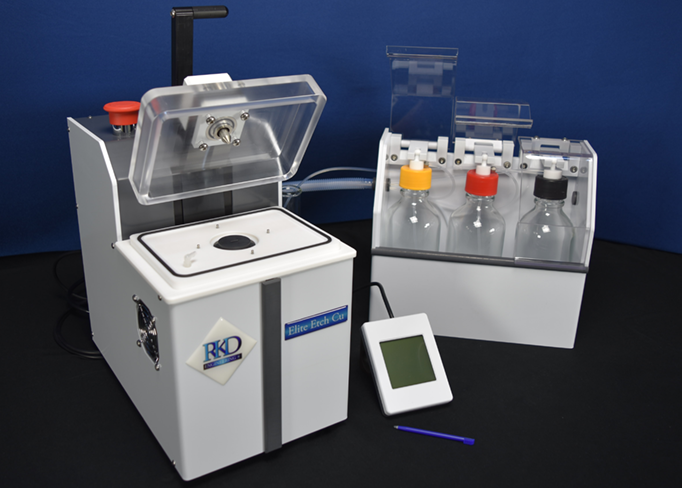

The Elite Etch Cu ESD from RKD Engineering is an automated mixed acid decapsulator which enables high productivity through the integration of advanced features. This decapsulator rapidly opens delicate integrated circuit packages by delivering precise, micro-aliquots of nitric, sulfuric, or mixed acids to a sample surface.

This ESD model includes an ESD mitigated environment to prevent dangerous static discharge which could potentially damage circuits in an IC package.

Fully featured decapsulation with ESD mitigation

The Elite Etch Cu ESD 7200 model incorporates critical ESD protection circuitry, thereby eliminating the potential for incremental ESD damage to fragile packages during decapsulation. In traditional non-conductive PTFE, a charge may build up on the inner surface of the acid line tubing and any residual electrical charge cannot be neutralized. If the charge exceeds the dielectric strength of the PTFE, dielectric breakdown occurs. ESD hazards associated with PTFE are eliminated in this system by the use of electrically dissipative PTFE.

The Elite Etch Cu ESD 7200 is equipped with a conductive ram nose connected to a high impedance resistor network to aid in ESD mitigation during decapsulation. The plastic encapsulated IC itself is of particular concern to justify working with a static-free environment. The solution is an electrically isolated yet dissipative ram nose assembly combined with the electrically functional PTFE. These components ensure that the process of decapsulation eliminates all ESD risks within the part being opened. The system is equipped with two ESD panel mounted sockets and circuitry for the attachment of ESD tweezers and a wrist strap. The wrist strap can be worn to mitigate ESD problems when handling a decapsulated package- including removal of the part from the decapsulator, rinsing, or drying.

Specifications

| Etcher Unit | Height: 300 mm (13 in) |

|---|---|

| Width: 190 mm (7.5 in) | |

| Depth: 305 mm (12 in) | |

| Bottle Assembly | Height: 254 mm (10 in) |

| Width: 280 mm (11 in) | |

| Depth: 127 mm (5 in) | |

| Weight | Approx. 16 kg (35 lb) |

| Power Source | 90 to 250 VAC, 50 to 60 Hz (4 amp) |

| Acid temp. range | 10° to 250° C |

| Acid temp. set point | 1° C ± 1% of setting |

| Etch cavity (up to) | 22 mm x 22 mm (30 mm diagonal) |

| Choice of Acids | fuming nitric acids, mixed fuming nitric and sulfuric acids, or fuming/concentrated sulfuric acid |

| Acid Mix Ratios | (nitric to sulfuric ratios) 9:1, 6:1, 5:1, 4:1, 7:2, 3:1, 5:2, 2:1, 3:2, 1:1, 1:2, 1:3, 1:4, 1:5 |

| Post Etch Rinse Options | sulfuric acids, fuming nitric acids, mixed acids, or no rinse |

| Etch Times | 1 to 2,400 seconds in 1 second increments (1 seconds to 40 minutes) dynamic (real time) adjustments of etch time |

| Etchant Volume Selection | 1 to 8 ml per minute - for all acids & acid mixes |

| Etch Delivery Functions | pulsed or Reciprocal Etch Acid Pulse (REAP) for lower acid consumption |

| Operator Program Storage | 100 programs stored to nonvolatile memory |

| Ambient Temperature Range | 15° to 26° C |

| Ambient Humidity | 0 to 70% non-condensing |

| Warranty | most comprehensive and inclusive warranty in industry (ask for full details) |

| Basic Model | Recommended | |||

|---|---|---|---|---|

| Elite Etch 7000 | Elite Etch Cu 7100 | Elite Etch Cu ESD 7200 | Mega Etch 7300 | |

|

|

|

|

|

| Dual Acid Decapsulation | ||||

| Dual Acid Decapsulation | ✔ | ✔ | ✔ | ✔ |

| Mix Ratios Settings | ||||

| Mix Ratios Settings | ✔ | ✔ | ✔ | ✔ |

| Touchscreen Interface | ||||

| Touchscreen Interface | ✔ | ✔ | ✔ | ✔ |

| Bottle Box Included | ||||

| Bottle Box Included | ✔ | ✔ | ✔ | ✔ |

| Silicon Protective | ||||

| Silicon Protective | ✔ | ✔ | ✔ | ✔ |

| Aluminum Protective | ||||

| Aluminum Protective | ✔ | ✔ | ✔ | ✔ |

| Gold Protective | ||||

| Gold Protective | ✔ | ✔ | ✔ | ✔ |

| Rapid Cooling System | ||||

| Rapid Cooling System | ✔ | ✔ | ✔ | |

| Copper Protective | ||||

| Copper Protective | ✔ | ✔ | ✔ | |

| Silver Compatability | ||||

| Silver Compatability | ✔ | ✔ | ✔ | |

| ESD Mitigation Control | ||||

| ESD Control Included | ✔ | ✔ | ||

| Direct Board Decapsulation | ||||

| Direct Large Board Decapsulation | ✔ | |||