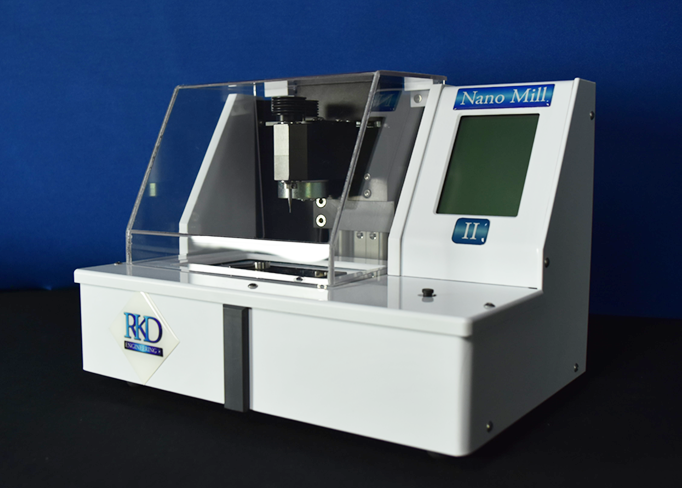

Nano Mill II 5100

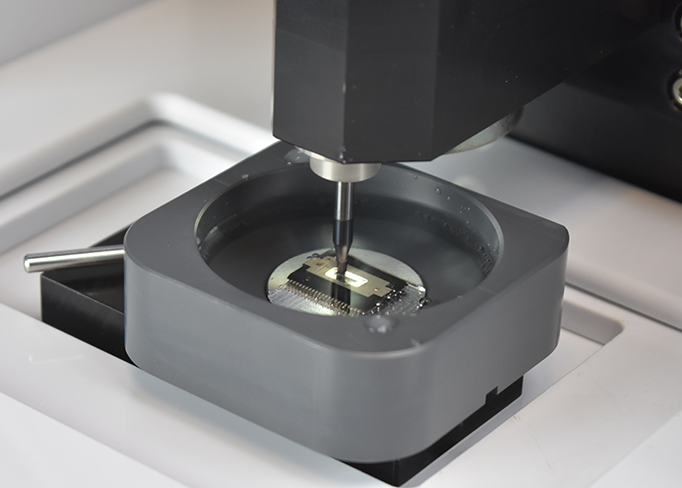

The Nano Mill II 5100 is designed to make custom fitted gaskets and fixtures for use with RKD Engineering decapsulators. It also performs mechanical decapsulation and heat spreader removal in preparation for wet etching. The system is an easy to use solution for quick turn decapsulator tooling and sample preparation.

The Elite Etch series functions ideally with a correctly sized gasket, making the Nano Mill II a common accessory unit.

Custom gasket formation and precavitation of IC packages

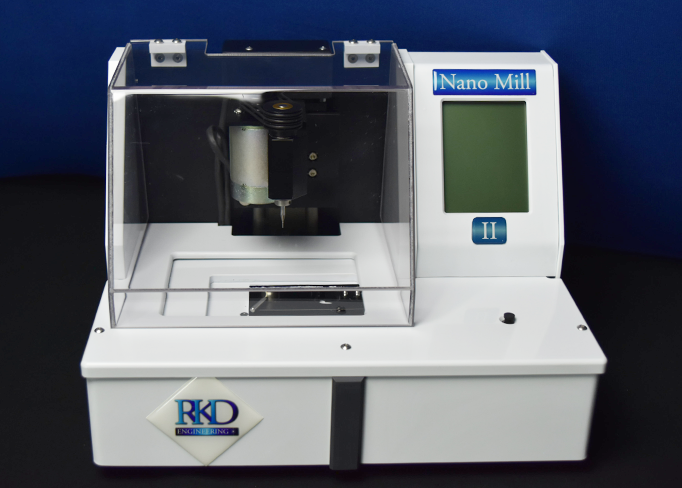

The Nano Mill II has a touchscreen user interface which gives the operator the ability to enter the key device measurements and perform desired functions at ease. The software is intended to be user friendly and does not require prior knowledge of machining operations or machine programming. The system provides many benefits to the decapsulation process. This includes making precision fixturing, shorter process and etch time, reduced acid waste, removal of messy sealants, and elimination of the probability of acid blowouts from multi-gasket stack ups.

Gaskets are essential for wet etching and the Nano Mill II has the ability to create holders for all industry standard form factors. A precut gasket material is available in two different diameters with adhesive backing used like a sticker.

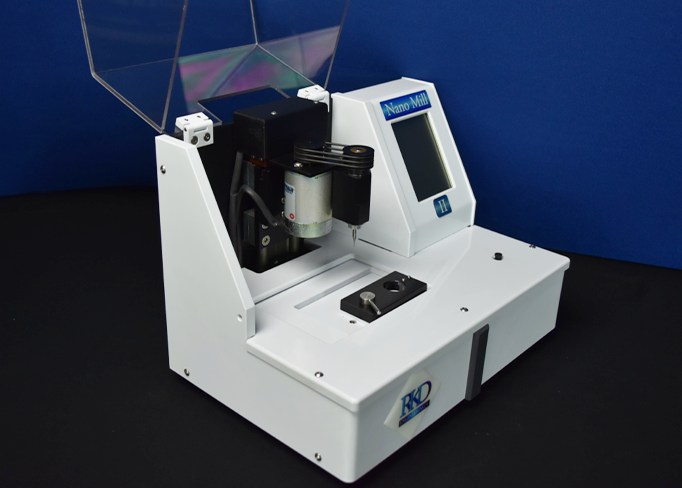

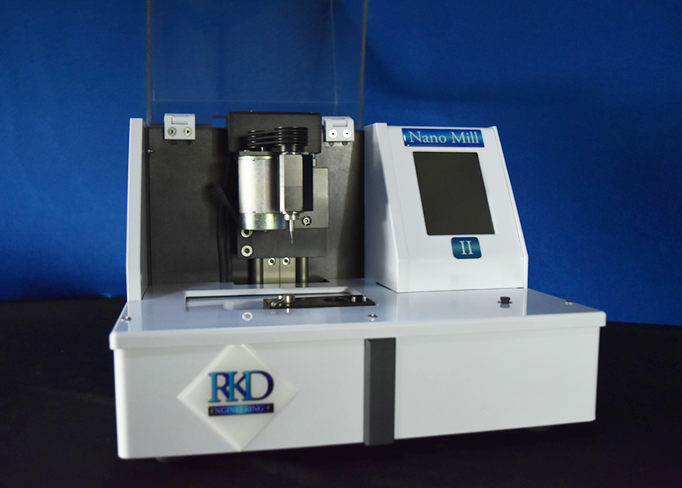

The Nano Mill II includes a kit with all required tools to begin immediate operation. A gasket holder is included to mount blank gaskets for custom sized definition cuts. Part holders are included to mount integrated circuits for precavitation, heat sink removal and more. Holders are simply placed in the mill to be machined via a clamping vise fixture table.

The Nano Mill II uses basic end mill standards which are placed directly into the spindle housing with a quick tool change setting. Gasket blanks are available in diameters of 25 mm (1 in) and 35 mm (1.375 in) with thicknesses of 0.8mm (0.031 in), 1.6 mm (0.063 in), 2.36mm (0.093 in), and 3.18 mm (0.125 in).

Features:

• Fast, easy set up, including alignment

• Simple operator interface with full process programmability

• Eliminates gasket purchasing lead times

• Makes any gasket required for acid decapsulation

• Removes heat spreaders and heat slugs

• Easy and fast mechanical decapsulation

• Available and inexpensive tooling

• Small footprint - takes minimal bench space

Specifications

| Dimensions | Height: 228 mm (9 in) |

|---|---|

| Width: 305 mm (12 in) | |

| Depth: 216 mm (8.5 in) | |

| Weight | Approx. 6 kg (13 lb) |

| Power Source | 90 to 250 VAC, 50 to 60 Hz (4 amp) |

| X Axis Travel | 50 mm (2 in) |

| Y Axis Travel | 50 mm (2 in) |

| Z Axis Travel | 38 mm (1.5 in) |

| Feed Rate | 250 mm/min (10 in/min) |

| Z Axis Repeatability | +/- 12 µm (0.0005 in) |

| Spindle Accuracy | +/- 12 µm (0.0005 in) |

| Spindle Speed | 7,000 RPM |

| Material Resolution | 10 µm finish |

| Tool Holder | Fixed into Spindle Shaft at 3.175 mm (0.125 in) |

| Tool Shank Diameter | 3.175 mm (0.125 in) required |

| Tool Preset Length | 18 mm |