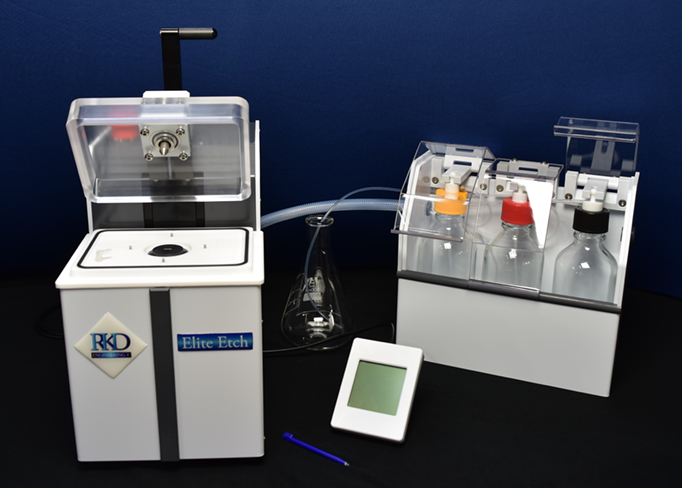

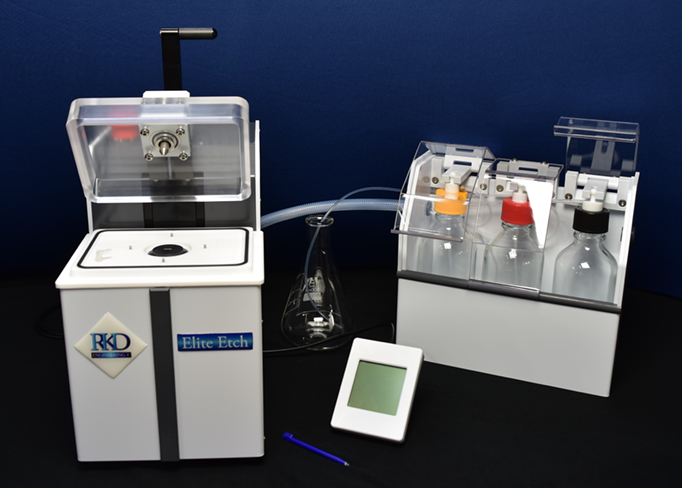

Elite Etch 7000

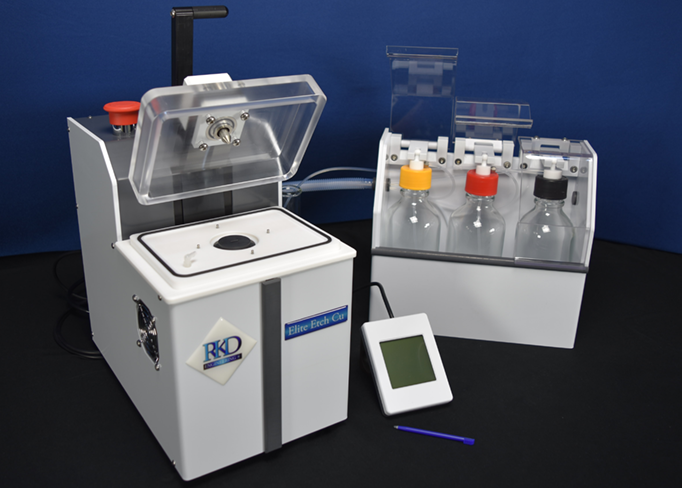

The Elite Etch 7000 is our first-generation automated mixed acid decapsulator. With advanced features, this decapsulator rapidly and easily opens a wide range of delicate packages by delivering precise, micro-aliquots of nitric, sulfuric, or mixed acids to the sample package.

The delivery of each micro-aliquot is cycled with enough pressure to create extreme turbulence in the etched cavity, greatly accelerating the rate of encapsulant removal. A precise acid temperature combined with a high delivery rate allows decapsulation without the risk of bond wire damage.

The first-generation automated mixed acid decapsulator

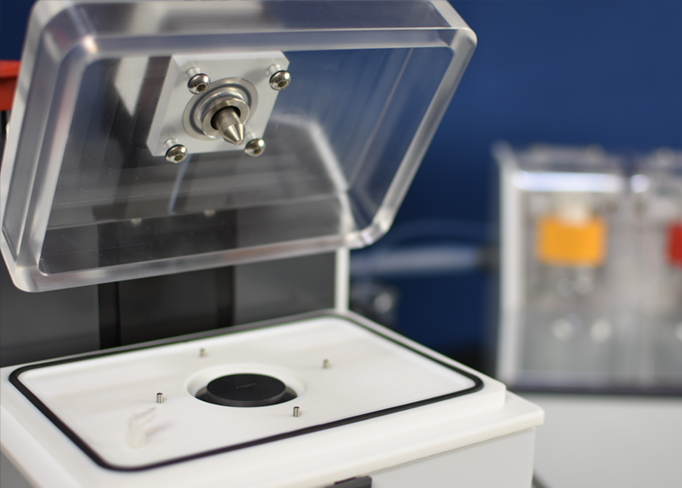

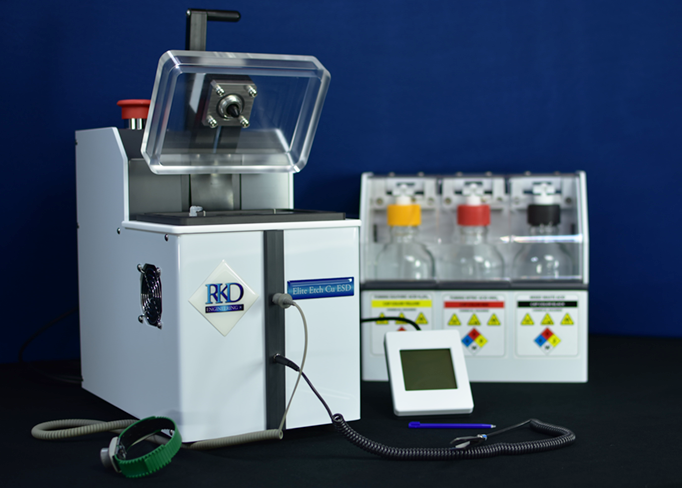

RKD Engineering’s Elite Etch incorporates the latest innovations. The etch head is machined from premium grade silicon carbide for its extreme acid and temperature resistance. Coupled with an active nitrogen gas monitoring and purge system, this monolithic design to reduces the fuming of residual acids left on the etch head after each decapsulation process. The silicon carbide etch head enables short heat-up times with high thermal conductivity.

The device hold-down assembly (ram nose) is a pneumatically activated and is designed for a large amount of travel. The ram nose only extends when the safety cover is fully closed to ensure absolute vertical movement. The ram nose secures the sample to the etch head, thus eliminating movement of either the package or its fixturing.

The safety cover is operated manually for safe control of the operation. This guarantees to the operator that the cover has sealed correctly. Acid flow lines and system assemblies are radially symmetrical compression joints which are engineered to eliminate high pressure seal failures.

The Elite Etch is designed to fit comfortably inside of a fume hood while maintaining all necessary safety features. By using a heat exchange system, waste acid is cooled below 90 C to allow the use of a single waste bottle. The Elite Etch uses 3 standard 500 ml bottles which are supplied with the system.

RKD Engineering incorporates double containment for all fluid couplings between the bottle container and the decapsulator. The bottle box assembly and the etcher unit both contain fluid sensors to alert the operator in the event of an acid leak from any of the bottles or internal fittings. The bottle box incorporates a universal pivoting interconnect which allows simple bottle exchanges.

Specifications

| Etcher Unit | Height: 300 mm (13 in) |

|---|---|

| Width: 190 mm (7.5 in) | |

| Depth: 305 mm (12 in) | |

| Bottle Assembly | Height: 254 mm (10 in) |

| Width: 280 mm (11 in) | |

| Depth: 127 mm (5 in) | |

| Weight | Approx. 16 kg (35 lb) |

| Power Source | 90 to 250 VAC, 50 to 60 Hz (4 amp) |

| Acid temp. range | 20° to 250° C |

| Acid temp. set point | 1° C ± 1% of setting |

| Etch cavity (up to) | 22 mm x 22 mm (30 mm diagonal) |

| Choice of Acids | fuming nitric acids, mixed fuming nitric and sulfuric acids, or fuming/concentrated sulfuric acid |

| Acid Mix Ratios | (nitric to sulfuric ratios) 9:1, 5:1, 4:1, 3:1, 2:1, 1:1 |

| Post Etch Rinse Options | sulfuric acids, fuming nitric acids, mixed acids, or no rinse |

| Etch Times | 1 to 1,800 seconds in 1 second increments (1 seconds to 30 minutes) dynamic (real time) adjustments of etch time |

| Etch Temperature Ranges | 20° to 90° C (nitric acid), 20° to 250° C (sulfuric acid), 20° to 100° C (mixed acids) |

| Etchant Volume Selection | 1 to 6 ml per minute - for all acids & acid mixes |

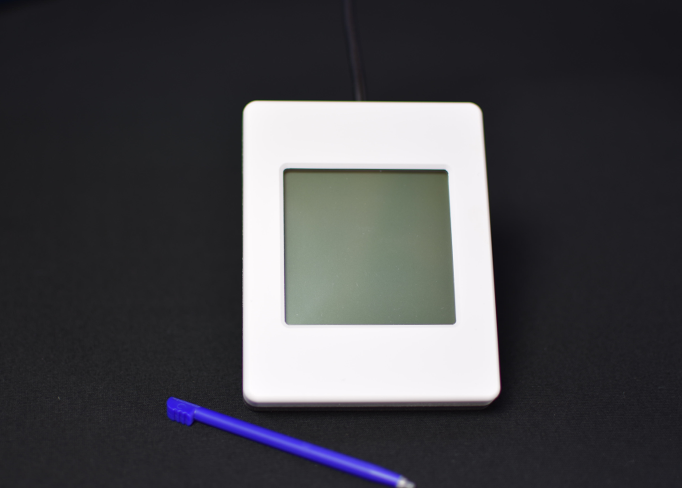

| Operator Program Storage | 100 programs stored to nonvolatile memory |

| Basic Model | Recommended | |||

|---|---|---|---|---|

| Elite Etch 7000 | Elite Etch Cu 7100 | Elite Etch Cu ESD 7200 | Mega Etch 7300 | |

|

|

|

|

|

| Dual Acid Decapsulation | ||||

| Dual Acid Decapsulation | ✔ | ✔ | ✔ | ✔ |

| Mix Ratios Settings | ||||

| Mix Ratios Settings | ✔ | ✔ | ✔ | ✔ |

| Touchscreen Interface | ||||

| Touchscreen Interface | ✔ | ✔ | ✔ | ✔ |

| Bottle Box Included | ||||

| Bottle Box Included | ✔ | ✔ | ✔ | ✔ |

| Silicon Protective | ||||

| Silicon Protective | ✔ | ✔ | ✔ | ✔ |

| Aluminum Protective | ||||

| Aluminum Protective | ✔ | ✔ | ✔ | ✔ |

| Gold Protective | ||||

| Gold Protective | ✔ | ✔ | ✔ | ✔ |

| Rapid Cooling System | ||||

| Rapid Cooling System | ✔ | ✔ | ✔ | |

| Copper Protective | ||||

| Copper Protective | ✔ | ✔ | ✔ | |

| Silver Compatability | ||||

| Silver Compatability | ✔ | ✔ | ✔ | |

| ESD Mitigation Control | ||||

| ESD Control Included | ✔ | ✔ | ||

| Direct Board Decapsulation | ||||

| Direct Large Board Decapsulation | ✔ | |||