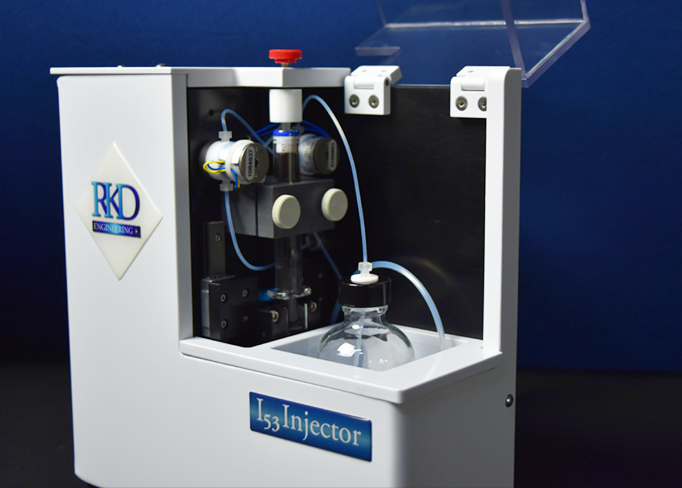

I53 Injector 7400

The I53 Injector 7400 is used to introduce low volumes of a solution into the acid stream of Elite Etch decapsulators. This solution is designed to create a more effective etching process and to prevent metal loss with samples that have silver alloy wires. The system is compatible with other custom corrosion inhibitors which can be formulated for other wire systems.

The solution to silver wire decapsulation

The I53 Injector contains a 250 ml source bottle with double containment and leak detection. A single, small diameter, PTFE tube transfers the solution to the Elite Etch system. A junction block is installed between the pump and heat exchanger of the Elite Etch and injects the solution into the acid stream. All components are made of acid resistant PTFE, PCTFE, or borosilicate glass.

The injection of the inhibitor is initiated by selecting the appropriate operation recipe. The programming screen has a selection of the ratio with a range of 20:1 to 40:1, acid to injector solution. The injection ratio applies to both etching and rinse. The syringe contains approximately 5 ml for a continuous dosage of solution for bond wire preservation.

When an I53 solution injection mode is selected from the handheld, a priming cycle is initiated. This cycle fills the syringe pump and the tubing to the junction block. This cycle purges any excess solution to the waste bottle and prepares for etching with corrosion inhibiting solutions.

On an existing Elite Etch system, the I53 Injector can quickly be installed using a serial communication cable connected from the I53 to the Elite Etch. The existing handheld is now plugged directly into the I53 and does not require additional software. The only modification to the etcher is the installation of the junction block and the routing of the solution tubing through the bottle box and into the I53.

Specifications

| Dimensions | Height: 230 mm (9 in) |

|---|---|

| Width: 230 mm (9 in) | |

| Depth: 127 mm (5 in) | |

| Weight | Approx. 16 kg (35 lb) |

| Power Source | 90 to 250 VAC, 50 to 60 Hz (4 amp) |

| Syringe Type | Hamilton gas tight 5 ml capacity |

| Resolution | 0.1323 μl |

| Cycle Volume | 0.0025 to 0.005 ml programmable |

| Mix Ratio | 20:1 to 40:1 |

| Dispense Accuracy | ±3%, ±0.14 μl |

| Refill Cycle Time | 60 second maximum |

| Source Bottle Size | 250 ml |

| Compatibilities | Elite Etch 7000 |

| Elite Etch Cu 7100 | |

| Elite Etch Cu ESD 7200 | |

| Mega Etch 7300 | |

| Warranty | most comprehensive and inclusive warranty in industry (ask for full details) |